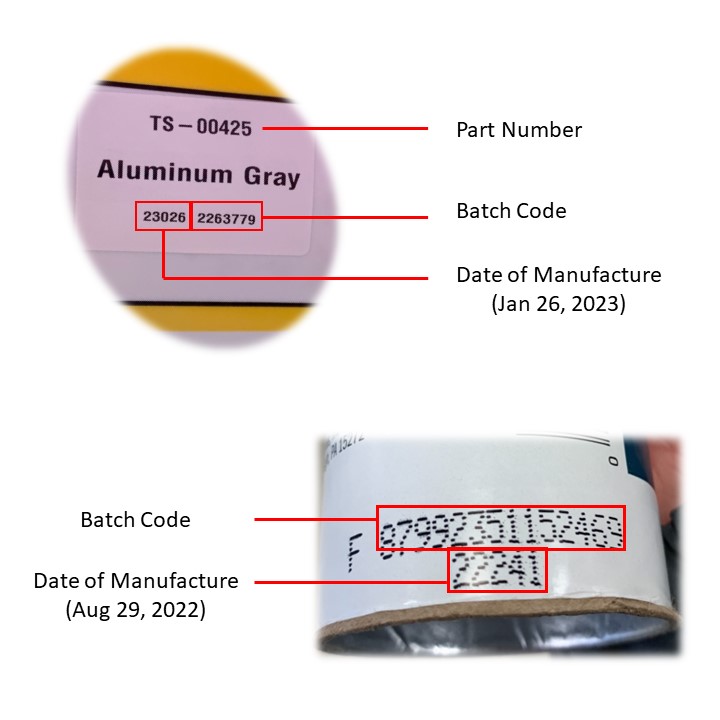

All TOWER Sealants products with the exception of TOWER Silicone have a 2-year shelf life (silicone has 1 year). There are two numbers printed on the bottom part of each tube, and on the side of each pail or sausage. The 5-digit number is the date of manufacture in Julian date format YYDDD. The longer number is the batch code. Here is a link to a Julian date converter

All TOWER Sealants with the exception of TOWER Silicone are paintable after skinning over. TOWER utilizes mainly water-based products with minimal, or often no plasticizers to prevent any shiners from forming after painting. This, paired with industry-leading consistency and air-free filling, gives TOWER caulks and sealants the best paintability on the market. Skin times vary for different products, the paint-time can be found on the Technical data sheet for each TOWER product, including spackling and patch. These TDS sheets can be found on each product page, or in the downloads page.

As a general rule, products should be kept above freezing, in a cool, dark area, away from direct sunlight. This will ensure the product will stay usable for the entirety of its shelf life. Should product freeze, make sure to move to a warmer area. TOWER products are all rated to perform through 5 freeze-thaw cycles. Viscosity, rhealogy and performance can be affected after each time the product freezes.

At TOWER Sealants, we recognize the standards of our professional customers, who rightly demand unparalleled quality and consistency. That's why we go the extra mile in our manufacturing process – vacuum-filled tubes, longer mixing times, a higher ratio of top-grade ingredients to fillers, and rigorous quality standards set us apart in the industry. We are committed to ensuring that every tube of our product maintains a uniform standard, offering both a tactile and performance consistency. Since 2006, we've consistently earned the trust of professional contractors, and we persist in advancing our sealant technologies, solidifying our position as the manufacturer professionals can depend on.

TCBSAT-30 is TOWER's internal testing method for adhesion to various substrates under real-world conditions. The acronym stands for TOWER Common Building Substrate Adhesion Test, and there are 30 substrates included in the testing. ASTM C-920 only tests adhesion to mortar, glass, and aluminum. This is very limited compared to the various substrates utilized in the construction industry, thus the TCBSAT-30 was created. Among the substrates tested are vinyl siding, PVC, fiber cement, brick, and various types of finished and unfinished woods. Sealant is extruded onto each substrate and left outside, facing the sun. Adhesion is tested periodically to measure various sealants' performance under real-world conditions, like UV exposure and weathering.

We have 13 stock colors, as well as many custom colors for various customers. We offer color-matching services to any customer willing to commit to purchasing the minimum required volume for a custom color batch. Please contact us for more information regarding this service.

Our technical support email is always available to answer any questions regarding which product to use, paint compatibility, project advice, or troubleshooting. Please send an email describing your question to tech@towersealants.com.

All TOWER SEALANTS products are <1.5% less exempt solvents, compliant with CARB standards, as well as <50 g/L less water and exempt compounds, according to SCAQMD standards. This makes all TOWER Products VOC-Compliant in all 50 states.

Plasticizers are substances that are added to polymers in order to soften materials, or to add more flexibility. Plasticizers are widely used in plastics, and can be found in many household items, such as shower curtains, car dashboards, and garden hoses. They are relatively low-cost when compared to other polymer additives, and can be used to increase performance characteristics of sealants, such as elasticity or flexibility. Plasticizers are a liquid, and can unfortunately migrate out of the intended products, and this is where they can cause issues for sealants; if the plasticizer migrates out of the sealant, it will cause the sealants itself to become more brittle, losing it's flexibility, and hindering its performance and ability to handle dynamic joint movement. The plasticizer can also often migrate into the paint coating over the sealant, and this can cause the paint to have a shiny blemish. This also will cause the paint to become tacky, and attract dirt, mold & mildew.

Some plasticizers are more prone to migration than others, and TOWER utilizes low-levels of plasticizers in some formulas, but our AU-1 and Tower Tech 2 contains no plasticizers, ensuring perfect paintability, and true performance that lasts the lifetime of the joint.