Are you facing issues from beam or crown molding caulk cracking? While it may seem like the caulk is to blame, the real culprit could be the wood itself, especially if this is a new build or project. New or green wood is susceptible to shrinkage and movement caused by changing atmospheric conditions or being installed with excessive moisture content, and these factors can lead to separation, and cracking in caulk beads and painted joints. Green wood also absorbs the moisture from fresh caulks, greatly affecting the adhesion of the caulk to the substrate.

Thankfully, there's a solution to help prevent this issue. By priming the green wood substrate before applying caulk, you can create a protective barrier that prevents moisture from the caulk from being absorbed into the wood. It also helps to acclimate the wood trim substrates to the home, allowing the shrinking to occur before installing the trim, or at least caulking it. It should also be noted that a low-cost commodity caulk cannot offer the movement capabilities necessary to handle this type of compression and elongation, so should you foresee this type of separation being an issue, make sure you are utilizing a product with an ASTM C-920 rating, such as TOWER Accura TT-S, AU-1 or TOWER TECH²™. These extra steps can ensure that the caulk adheres correctly and stays intact, giving you a flawless finish that stands the test of time.

Are you facing issues with shiners appearing after painting over caulking? Shiners are formed from plasticizers in the caulking migrating into the paint over time. Plasticizers are a very common ingredient in sealants, and are used to give the product more flexibility. The downside of adding plasticizers to a formula is they often migrate out of the caulk bead and into the substrate, or in many instances, the paint. As plasticizers migrate out of caulking, making the bead more brittle, they will cause the paint to appear shinier than in other areas. This is not the only problem with this blemish either; the leached plasticizer causes the painted surface to become tacky, attracting dirt, and eventually mold and mildew. You might see this type of streaking appear under windows over time.

Plasticizers often have utility. Many high quality sealants contain plasticizers, and some of these are more compatible with paint than others, but the only way to ensure that a job will result in no shiners or discoloration from plasticizer migration is to utilize a product with no plasticizers. TOWER Sealants provides many premium products that contain no plasticizers, two of which are AU-1 Elastomeric Construction Sealant, and TOWER TECH²™.

Why is my new caulk turning yellow? Certain caulks may have a tendency to yellow or discolor over time, especially when exposed to sunlight or harsh environmental conditions. This can be particularly problematic when using white or light-colored paint. In some cases, caulk can degrade or crumble over time, moreso when exposed to extreme temperatures or moisture. This can result in sealant failure and costly reapplication. Yellowing caulk can even be observed on interior jobs that are exposed to UV regularly.

The only way to ensure that your caulking will not discolor or degrade from UV exposure is to choose a product with exceptional resistance. Certain formulations and additives offer more protection from UV exposure, and certain technologies resist UV damage better, with the best being acrylics.

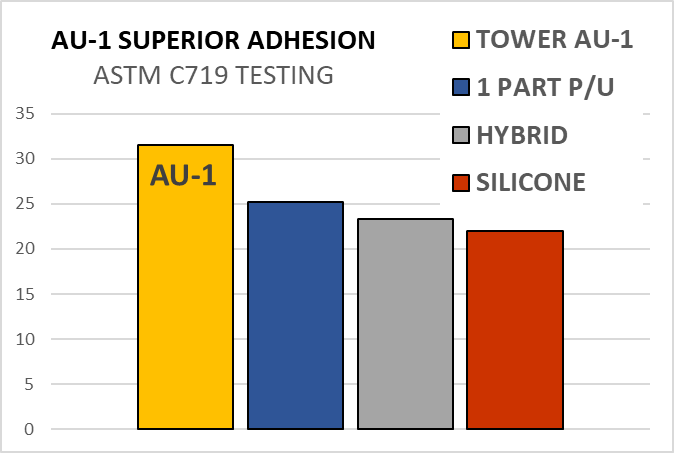

Paired with a robust UV-resistance package, TOWER's AU-1 shows best-in-class UV resistance, especially when compared to the competitor Polyurethane and solvent technologies. TOWER Sealants' internal, real-world testing involves placing our products, along with competitors' products on 30 common building substrates, on a fence facing the sun. From all of the data we have gathered from periodic testing, AU-1 outperforms all technologies and competitors in maintaining it's adhesion strength. Learn more about TOWER's internal testing method TCBSAT-30 in our FAQ page.

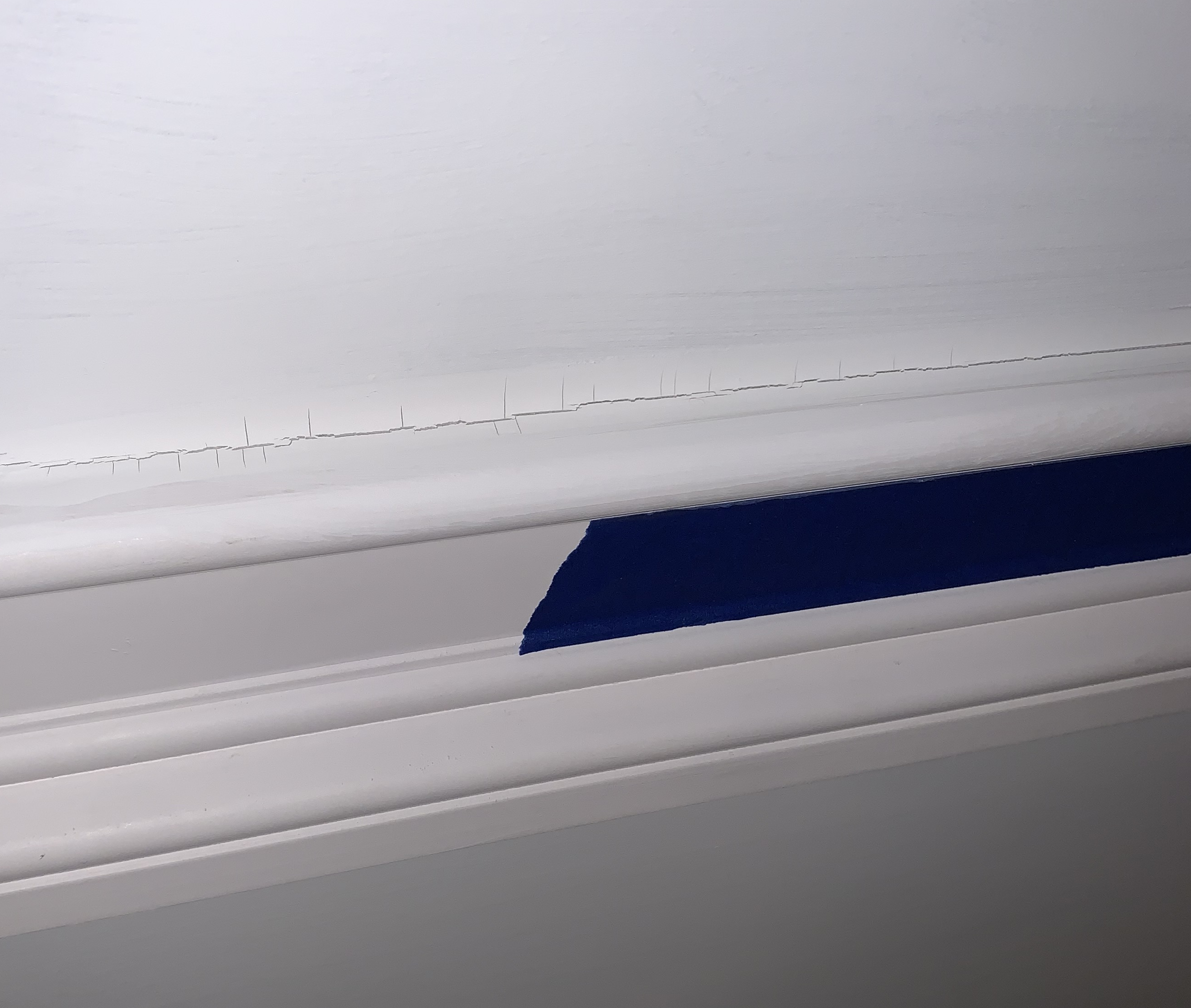

A common issue facing the professional is returning after a paint job to find the paint film has cracked over the caulk bead. There are a few reasons why this occurs, but the cracking is mainly due to the paint adhering to the caulk, and stretching as the caulk bead shrinks and cures.

As paint technologies have evolved, manufacturers have introduced an array of products with enhanced attributes, catering to various application needs. These products boast features such as easy touch-up, washability, mar resistance, and remarkably fast drying times. However, it is essential to consider the compatibility of certain paint types, with sealants. These paints typically dry to form rigid, non-flexible films. As a result, these films are not designed to accommodate flexing or stretching, which can become a concern when used in conjunction with caulks. Caulking for a paint job necessitates a substantial curing period, often spanning 48 hours or longer, as it evaporates the water from its system. During this curing process, natural shrinkage occurs in the caulk.

The challenge arises when the paint or primer dries at a faster rate than the caulk can fully cure. This disparity in drying times, along with the fact that the caulk bead is substantially thicker than the paint film (40 mils vs 1-3 mils) imposes significant stress on the interface between the caulk bead and the paint film, leading to film cracking.

If cracked paint has already occured, and needs to be fixed, please refer to our Paint Crack Repair Guide.

There are two ways to mitigate such issues and ensure a successful paint application. By giving the caulk adequate time to fully cure, the stress on the paint film is minimized, preventing the development of unwanted cracks and enhancing overall durability. We understand the challenge and delays involved with waiting for a full cure, and the strict timelines in construction and renovation jobs, and TOWER is happy to provide some other options. TOWER Sealants' formulas are engineered to consider the effect of the latest high performance paints, and can effectively minimize or eliminate paint film cracking. TOWER Sealants has spent years of compatibility and formula testing to ensure we can provide products that can work with every type of paint. TOWER's Accelerator and Accura TT-S are unique formulations that incorporate specific properties to address the issue of cracked paint in rigid coating systems. To ensure that your sealant selection is compatible with a certain paint, please contact us at tech@towersealants.com.