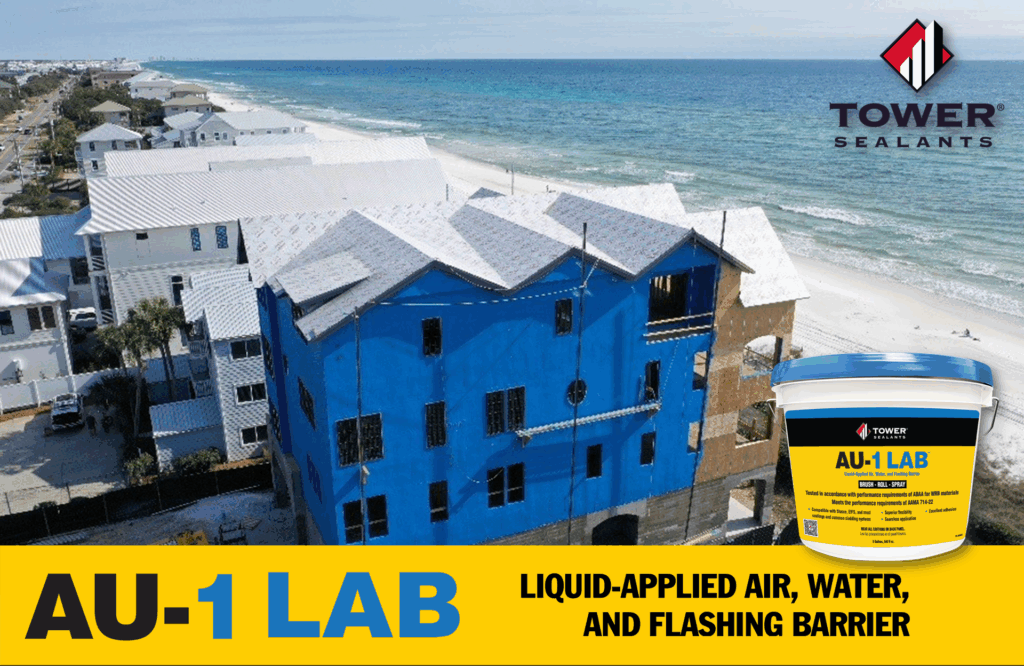

AU-1 LAB is a high performance, single component, Styrene Butadiene Resin (SBR) elastomeric liquid weather resistive barrier and flashing membrane. This weather resistive barrier (WRB) functions as both a membrane and flashing and is designed to protect structures from moisture intrusion, air leakage, and environmental stressors. This low-odor, waterproofing barrier can be sprayed, brushed, rolled or troweled, and requires no primer. It is formulated to provide a permanent, breathable waterproof seal with excellent adhesion to most common substrates, including green concrete. It is low VOC, easy to apply, and is easy to clean with soap & water. AU-1 LAB can be used on rough openings, around penetrations and on broad wall applications as a weather-resistive barrier.

| Vehicle: | 100% Styrene Butadiene Resin |

| VOC: | <50 g/L |

| Pigment: | Calcium Carbonate |

| Weight Solids: | Approx. 66.42% |

| Volume Solids: | Approx. 53.0% |

| Weight per Gallon: | 11.11 ± 0.5 |

| Specific Gravity: | Approximately 1.33 |

| Service Temp: | -30ºF to 180ºF |

| Temp Range (application): | 40ºF and rising. Air temp no hotter than 95ºF and substrate not hotter than 160ºF |

| Freeze Thaw Stability: | Passes 5 Cycles@ 0ºF (1 cycle = 16hrs. @ 0ºF, 8hrs at 75ºF) |

| Flash Point: | N.A. |

| Consistency: | Paste / brush-able |

| Applications: | Interior / Exterior |

| Life Expectancy: | 60-year performance |

| Shelf Life: | 18 months when stored at 50ºF to 80ºF |

| Odor: | Mild Acrylic |

| Working Time: | 10 to 20 Minutes |

| Tack Free Time: | 4 hours at standard conditions |

| Paint Over / Recoat: | 6 to 8 hours |

| Full Cure: | 24 to 72 hours |

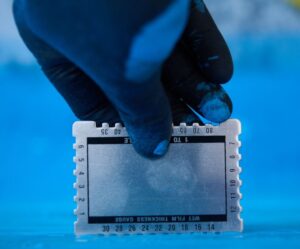

| Wet Mil Thickness: | 30 mil |

| Coverage (@ 30 mil wet) | 53.46 sq ft per gallon |

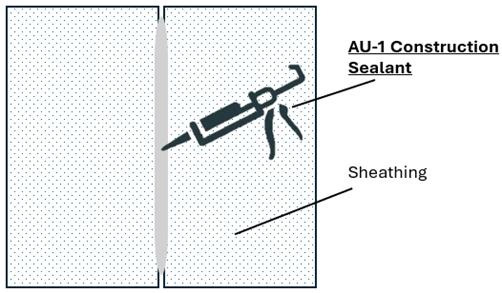

Surfaces to be free of all dirt, dust, oil, mildew, frost or other contaminants. Any structural damage must be repaired prior to application. Any non-structural cracks or joints up to ½” should be sealed with AU-1 Elastomeric Construction Sealant prior to Liquid-Applied Barrier Application. A primer is not needed for most common substrates; however, adhesion testing is recommended to ensure proper adhesion to the substrate. AU-1 LAB can be applied to green concrete. Protect property and surfaces not to be applied with membrane.

Do not induce air if product needs to be mixed. Do not dilute product.

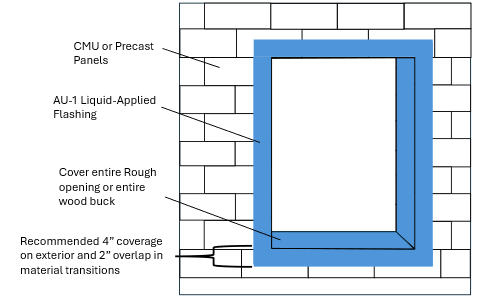

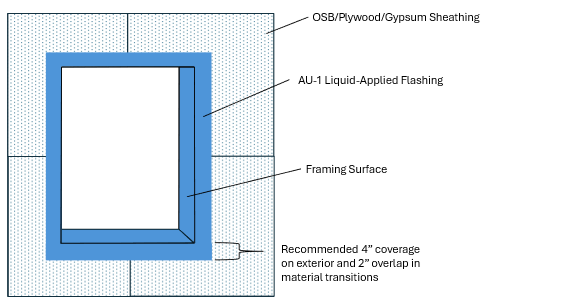

Use a brush, roller, sprayer or trowel to apply AU-1 LAB to a minimum of 30 wet mils over the desired area of the rough opening including the exterior surface. For airless spray application: a 1.15 – 2.5 GPM (gallons per minute) sprayer is recommended with a tip orifice size of .021 - .025 at 3000 PSI. Product should be back-rolled following airless spray application to ensure consistent coverage and eliminate pinholes. When back-rolling or for roller application, a minimum ¾” nap high quality roller is recommended. Application should be performed in a manner resulting in the membrane surface being free of openings or pinholes. Apply additional AU-1 LAB as needed to ensure a uniform coating with no pinholes. Allow the product to become tack-free before applying additional coats. Product may be applied up to 60 wet mils without sagging. Allow product to skin before installing any components into rough openings. Skin times may vary by humidity and conditions. Check local building codes for additional recommendations or requirements.

NOT INTENDED FOR AREAS THAT WILL BE SUBMERGED IN WATER. KEEP PRODUCT FROM FREEZING PRIOR TO APPLICATION / CURING. NOT FOR FOOD CONTACT SURFACES. PRODUCT CANNOT BE SANDED.

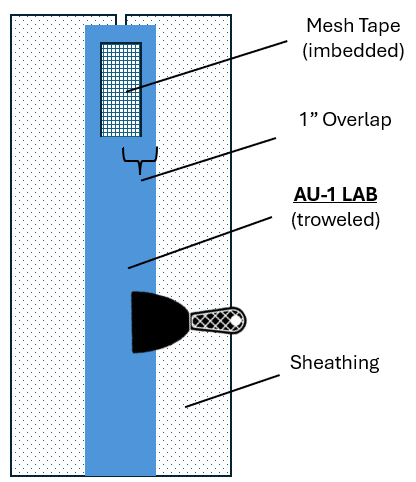

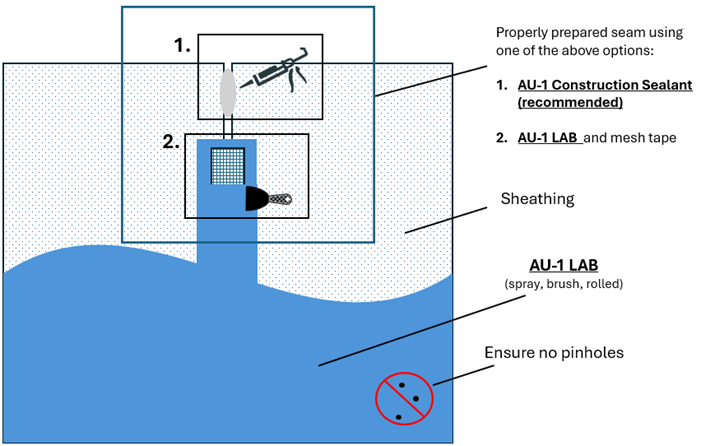

If applying over plywood/OSB sheathing, apply AU-1 Commercial Sealant or mesh tape and AU-1 LAB:

OPTION 1 (RECCOMENDED):

OPTION 2:

Apply AU-1 LAB as directed in the previous page around all rough openings as a liquid-applied flashing. Allow the product to become tack-free before applying AU-1 LAB across entire exterior surface.

Sheathing fasteners should be flush with the surface. Fasteners protruding or sunk below the surface should be sealed with AU-1 Commercial Sealant.

Once all seams and rough openings have been properly prepared as described above, use a brush, roller, or airless sprayer to apply AU-1 LAB to a minimum of 30 wet mils over the exterior surface. Use a wet mil gauge to ensure proper mill thickness. For airless spray application: a 1.15 – 2.5 GPM (gallons per minute) sprayer is recommended with a tip orifice size of .021 - .025 at 3000 PSI. Product should be back-rolled following airless spray application to ensure consistent coverage and eliminate pinholes. When back-rolling or for roller application, a minimum ¾” nap high quality roller is recommended. Application should be performed in a manner ensuring the membrane surface is free of any openings or pinholes. Apply additional AU-1 LAB as needed to ensure a uniform coating with no pinholes across the entirety of the membrane. Allow the product to become tack-free before applying additional coats. Product may be applied up to 60 wet mils without sagging. Allow product to become tack-free before installing cladding or any components into rough openings. Tack-free times may vary by humidity and conditions. Check local building codes for additional recommendations or requirements.

AU-1 LAB should be covered within 9 months after application to prevent possible UV damage. Install proper cladding as required by manufacturer instructions. AU-1 LAB is self-sealing and does not require additional sealing around properly installed cladding fasteners.

Ensure exterior walls are capped or protected to prevent moisture intrusion. Ensure barrier is integrated with roofing system where wall meets roof / soffit, etc. Ensure barrier is integrated with other building wrap / waterproofing systems per manufacturer's instructions.

NOT INTENDED FOR AREAS THAT WILL BE SUBMERGED IN WATER. KEEP PRODUCT FROM FREEZING PRIOR TO APPLICATION / CURING. NOT FOR FOOD CONTACT SURFACES. PRODUCT CANNOT BE SANDED

Immediately after use, clean uncured material and tools with soap and water. Remove cured membrane by cutting with a sharp-edged tool.

Only apply AU-1 Liquid-Applied Flashing when product, surface, and air temperatures are above 40° F and rising. Do not apply on surfaces exceeding 160° F. Do not apply to frozen substrates, prior to extreme weather, or before heavy rain. AU-1 Liquid-Applied Flashing is not for use in below-grade applications, or in areas where frequent water ponding may occur. Product is not intended for use on surfaces where it will be permanently exposed.

AU-1 Liquid-Applied Flashing should be stored in original, unopened containers, away from heat and direct sunlight. Product should be kept from freezing. When stored correctly, product will have a shelf life of 18 months.

Warranty: TOWER Sealants warrants this product to be free from manufacturing defects. The installer is responsible for the testing of this product on the surfaces of the targeted application for compatibility and performance prior to use. This is the sole and exclusive remedy and liability for defects or failure of this product. THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, WRITTEN OR ORAL, STATUTORY, EXPRESSED OR IMPLIED; INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS.