Installing expansion joints in concrete with sealant is an important part of construction work. It ensures that buildings remain weather-tight and resistant to water damage. However, using the wrong type of sealant, or not applying it correctly, can lead to costly and time-consuming problems down the line. This is why it's important to choose the right sealant for the job and follow the manufacturer's expansion joint installation instructions carefully.

One of our fastest-growing products right now for exterior applications is AU-1, a one-part, low-odor, gun-grade, elastomeric construction sealant. In this article, we'll provide an in-depth look at AU-1, including its properties, recommended applications, testing, surface preparation and installation procedures, as well as tips for ensuring optimal results.

AU-1 is an ASTM C-920, Type S, Grade NS, Class 35 sealant, made from an aqueous-based urethane acrylic polymer. It is one of the first high-performance sealants of its kind for the commercial building industry. The active ingredient in AU-1 is an Aqueous Polyurethane Dispersion, which is an internally plasticized resin that requires no mixing or priming to bond molecularly to most concrete expansion joint material. AU-1 is paintable with no shine-through or plasticizer bleed, and is VOC-compliant nationwide, including all CARB and SCAQMD requirements, and requires no additional job-site solvents for prep or cleanup. AU-1 is also extremely UV resistant and maintains high elasticity in all climates.

Prior to any project, TOWER Sealants recommends testing or project mockup to be performed at the job site, under the same conditions as the planned project. TOWER will provide compatibility and adhesion testing upon request, as well as field testing assistance and guidelines. Please contact TOWER for guidance on peel adhesion testing protocol for waterproofing projects.

Surface preparation is crucial for achieving a strong and long-lasting sealant bond. Before applying TOWER Sealants' AU-1 Construction Sealant, it is important to ensure that the surface is dry, clean, and free from any dirt, dust, oil, mildew, loose paint, old caulk, or other contaminants. Additionally, the sealant, surface, and air temperatures must be above 40°F and rising during application, and surfaces should not exceed 140°F. Do not apply the sealant to frozen substrates, prior to extreme weather, or before heavy rain. The sealant is also not recommended for use in below-grade applications or areas where frequent water ponding may occur.

When dealing with new construction, joints should be capped or protected at the top if the roof has not yet been installed. The preferred method would include a water drainage system at the bottom of the joint. If the sealant is being applied to horizontal joints, it is recommended to avoid areas receiving foot traffic as AU-1 remains too flexible for heeled footwear.

AU-1 Construction Sealant does not require priming for most applications, including concrete, metals, and other porous and non-porous substrates. However, for substrates that are generally difficult to bond to, it is advisable to contact TOWER for primer recommendations. To retain substrate integrity, crumbling/powdering, friable, or porous substrates should be primed with a penetrating primer before sealant application.

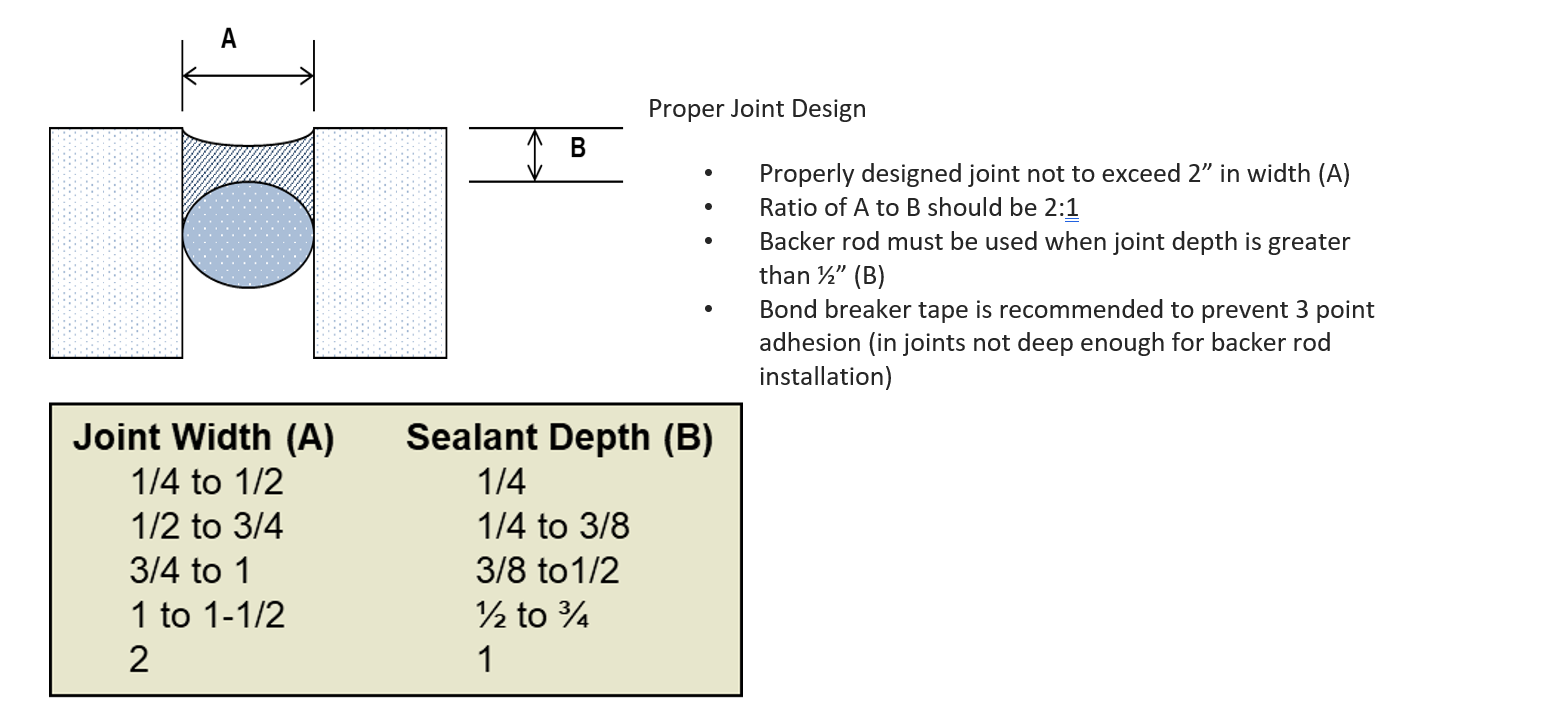

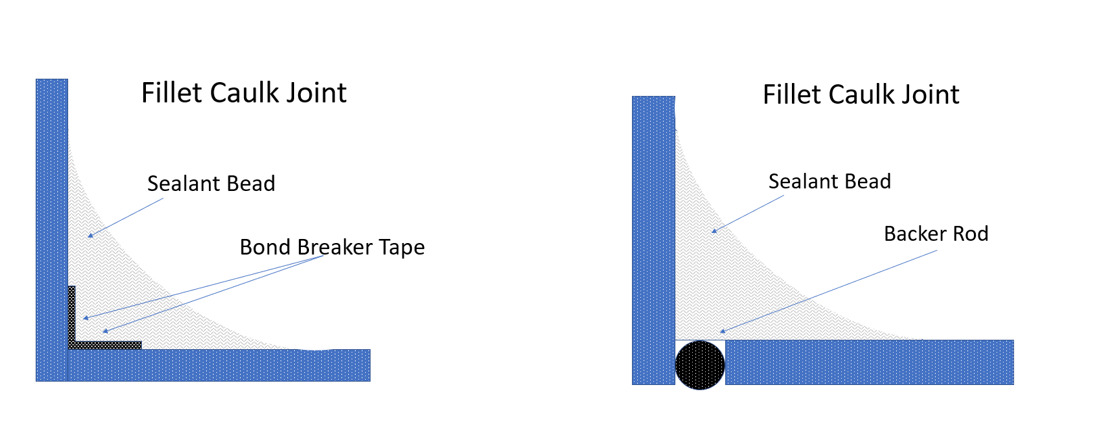

When it comes to sealing construction joints in concrete, TOWER Sealants recommends designing joints in compliance with the ASTM C1193 Standard Guide for use of Joint Sealants. Specifically, for 90° fillet joints in window openings, a minimum bead size of 3/8” after tooling is recommended.

Once the sealant joint design is established, to prevent 3-point adhesion in the joint, caulk backing material must be installed. TOWER recommends using an open or closed-cell, circular backer rod that fits the joint walls. If the joint depth is not great enough to allow for concrete expansion joint installation of a backer rod, a bond breaker tape should be used. If the backer rod is painted preceding sealant application, rotating the backer rod will reduce the potential of 3-point adhesion.

After the caulking backing material is installed, it's time to apply TOWER Sealants' AU-1 Construction Sealant. Before opening any sausages, cartridges, or pail, complete all preparatory work. AU-1 requires no mixing before use, making it ready to be applied as soon as the container is opened. While dispensing the sealant through a cartridge or bulk applicator gun, it's crucial to ensure that the entire joint is being filled with the sealant, leaving no air in the joint. Also, the sealant must be in contact with both substrates through the entirety of the joint, ensuring a waterproof seal.

Once AU-1 Sealant is applied, tooling is recommended with a flat tool. AU-1 must be tooled within 15 minutes of application for best results. TOWER requires that the joint is tooled flat, or flush with the substrate. The flat tooling, along with AU-1's evaporative cure, will allow for an ideal hourglass-shaped joint.

After tooling and prior to sealant curing, any excess sealant on the substrates can be wiped clean with a cloth and water. AU-1 cannot be sanded, and tools can be cleaned with water, and soap if necessary.

The cure time of AU-1 varies with temperature and humidity. At 50% relative humidity, at 75° F, tack-free time is 30 minutes, and most paints can be applied after 6-8 hours. In the case of lower temperatures and/or higher humidity, painting should be delayed until the sealant has time to skin. Do not apply AU-1 before heavy rain, as this can delay cure, wash sealant out if a skin has not formed, and further affect performance. For larger joints, AU-1 has a typical cure time of 21 days, and peel adhesion testing should not be performed until a full cure is reached. Please contact TOWER technical support for additional information on recommended cure time. After full cure, AU-1 has a service temperature range of -40°F to 180°F.

To ensure that AU-1 stays effective, it should be stored in original, unopened containers, away from heat and direct sunlight. The product should be kept from freezing, and when stored correctly, it has a shelf life of 24 months.

When designing and applying joints in construction, it's crucial to follow the ASTM C1193 Standard Guide for use of Joint Sealants and use the recommended backing material and sealant. TOWER Sealants' AU-1 Construction Sealant is easy to apply and clean up, and with proper application and curing, it will provide a durable, waterproof seal that will last the lifetime of the building.